Robotics can help fashion companies drive business efficiencies in their warehouses, stores and factories. In the 1990s, fashion’s relationship with robots was a fantasy. Today, the industry’s interaction with automation is much more common and tighter.

In the distribution centers of e-commerce leaders, robots, controlled solely by their own software, routinely roam the giant warehouses, collecting and transporting goods faster and more accurately than humans. This new increase in efficiency has enabled new services such as the delivery of an online purchase on the same day of the transaction.

These new automated systems for storage and retrieval of the product have generated a greater density in its positioning and provide more precision in inventory management. The objective is to offer a high level service that is key today for fashion brands: delivery on the same day of purchase. The robots take the items from the storage systems and take them to packing stations with human personnel, where the information seen on the screens instructs the operator on where and how to allocate the stock to the purchase orders received.

More efficient fashion retail.

Robots could also improve efficiency in retail as sales tasks such as checkout, stock replenishment and inventory control will be performed by robots. Customers will increasingly use mobile technologies to access information and receive advice while in the very physical stores.

As the pace of automation continues, both in the fashion industry and in the economy at large, robotic technologies and automatic learning technology are likely to eventually automate almost any job that has some level of routine and is predictable.

This will challenge companies to develop plans for human-robot collaboration and implement these technologies gradually to give the organization and its workers the time they need to adapt to change. Fashion is now in a position to follow the example of industries such as automotive and electronics, which have previously resorted to robotics to implement just-in-time manufacturing and delivery.

Personalization relaunches relocation.

Most of the leading brands of sportswear are very advanced in the relocation process through automation of their production with the aim of satisfying in the shortest possible time the growing desire of today’s customer to customize the product they purchase.

In pursuit of this goal, the factory is transformed into a center for the production of personalized products, which is one of the most important trends in the sector. In this way, customers can request the customization of the model they buy, manufacture or semi-manufacture it in a robotic factory near the mall and make the delivery in a matter of hours.

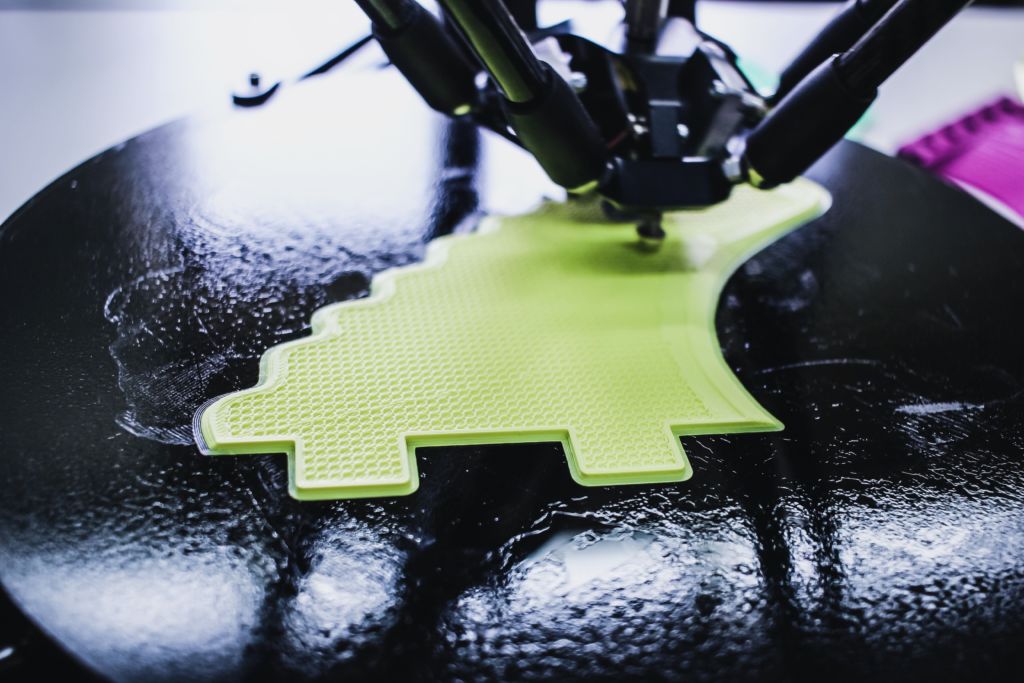

Custom fashion printed in 3D.

For many years now, fashion accessories or their constituent parts have been made from industrial molds. These rigid and hollow blocks are filled or injected with the liquefied material selected for that product, be it plastic, glass, resin, other derivatives or some metal alloy, which later hardens adopting the shape of the mold. Once created, the molds are used to cost-effectively manufacture large series of identical products. But because the cost of these traditional molds is very high, they are not useful for limited production, individual or customized products.

The solution to this problem is the use of computer-controlled additive layer manufacturing technique, such as 3D printing. 3D technology prints objects by placing layers of the constituent material one over the other, based on a digital design. Because there is no initial investment in traditional molds, the use of this technique makes the individual cost of the product for one unit the same as for producing 10,000 units, radically reducing entry barriers to fashion customization.

However, for this technique to become a practical means of producing individualized luxury products, the next generation of 3D printers must be able to mix optimal materials and achieve top quality finishes. At the moment, this is happening, but on a research level and with expensive prototypes.

Automation of the fashion industry.

But beyond the advance of robotics in relation to electronic commerce, as we said at the beginning of the present article, the fashion industry has not adopted it fully and in its entirety. Its adoption is slow even though robots have become smarter, driven by advances in artificial intelligence, and cheaper by progressive improvements in technology and new materials.

So, compared to other industries, the use of robots in garment manufacturing remains scarce. This is partly due to a key technical challenge, while automobiles or electronic products, almost entirely assembled through robots, are largely composed of hard parts, garment manufacturing involves the use of flexible and elastic fabrics that have traditionally made it difficult to automate the process.

While there are solutions to these problems, through software that interprets the behavior of the fabric in real time during the sewing process and generates the necessary adjustments, these robotic systems can make a limited range of basic clothing normally focused on fast fashion, sportswear and household items such as towels and curtains.

The textile and fashion industry needs robots.

At first glance, and in accordance with the conclusions drawn from the analysis of the customization of fashion items and the need to deliver the “customized” product on the same day of purchase, everything would indicate that automated factories only make sense in an industry relocated to developed countries, close to the physical stores or to the customer’s own market for home delivery.

If we take a closer look and analyze the commercial trends in relation to the industry, we can deduce that robotics is no longer exclusive to developed countries and their nearby factories. Rather, within the fashion industry, it is beginning to revolutionize and bring its immense value to production in the main centers of manufacture of clothing, footwear and accessories, both in Asia and Africa. In both origins most of these factories are located in less populated areas; even immersed in the “middle of nowhere”, in the case of African rural areas. Young people do not stay in these rural markets, they move to city centers in search of new opportunities. It is the owners and directors of these production centers themselves who know and express that within 10 years there will be no people in these areas to do this kind of work.

These same productive units already face, at present, the problem of the constant transfer of their qualified staff, in whose training time and money have been invested, to the service sector. In most cases, the textile and fashion industry is the first job for young people who move from the countryside to the city. Once they have adapted to the big cities, to their new living conditions and with a wider economic base than the original, they try to access other jobs in the very centers of the cities.

Labor Vs. Automation.

The conclusion comes from an enriching personal and professional experience during my last trip to Ethiopia.

As a result of my astonishment, when I contemplated 100,000 m2 of a new factory in the middle of an eminently rural area of Mekele, 100% automated for the production of jeans, my curiosity exploded and an irrepressible question arose and reflected addressed to its owner and sole investor:

- What is it that has led you to make such an important investment and set up a fully robotic factory in one of the last areas of the world with low-cost labor?

He replied without hesitation:

- My plan is medium-long term. Considering the new objectives of fashion brands, I need to create a very versatile and flexible factory that is capable of producing the current large volumes, but also and above all, the diversity of much more customized models and in small number of units that I will have to develop in the future. Total automation gives me this possibility.

I have written this article exclusively for AITEX and it has been published in its Magazine #60. Thank you AITEX! A pleasure to collaborate with your prestigious magazine!