International consulting firm Accenture observed nine circular fashion technology concepts that can be used to generate sustainable value and reach the next level of circularity. These concepts are divided into three main categories based on the characteristics of the technologies used: digital, physical and biological.

In this first article we provided you with the Accenture report “Circular x Fashion Tech Trend“, which you can download for free. Later, in this post that I recommend you read, we describe the digital technologies of fashion. Next we will analyze the second category which is physical technologies, those that are based fundamentally on the elemental properties of the material.

Physical technology of circular fashion

To protect Planet Earth, its resources and to enable a sustainable future, the physical concepts of fashion technology are very important. These concepts are based on technologies that use physics. Examples of this are the fundamental property of materials, the forces of nature and energy, as well as the interaction between these aspects. There are numerous physical concepts of fashion technology, which are divided into three main groups: 3D solutions, nanomaterials and robotics.

1. 3D solutions.

Imagine you press a button and your new pair of sunglasses or running shoes are instantly manufactured in your living room.

3D solutions, such as printing and scanning, offer new opportunities in sustainable production and sourcing. Now, you can finally get that perfectly tailored suit whenever and wherever you are. 3D solutions bring the fashion customer and the physical production site closer together.

When a garment is scanned and then printed in 3D, sequential layers of fabric are formed to create an item of clothing. The process is computer controlled and items can be manufactured on an industrial scale.

This approach allows for product development at the moment, in your living room or in your favorite store. It also minimizes the waste of raw materials, as well as packaging and transportation. This concept of fashion technology has the ability to generate custom garments that fit perfectly.

Sustainable Impact.

-

Personalized clothing with a perfect fit is likely to result in an increase in the rate of wear and a decrease in the amount of clothing thrown away after it has barely been worn

-

Faster production processes at the moment reduce dependence on long-term forecasts, decreasing the risks of overstocking clothes and therefore minimizing waste.

-

By having the consumer and production closer to each other, the need for packaging, transport and ultimately the carbon footprint can be reduced.

Challenges to overcome.

-

The level of sustainability is determined by the material used. Today, however, metal and plastic are two of the most frequently used materials, limiting the positive impact.

2. Nanomaterials.

Nanomaterials enable the fashion industry to move from traditional materials to new “smart” fabrics with novel capabilities, such as a nanoscale structure with unique optical, mechanical or electronic properties.

For example, this approach may include changes in the behavior of fabrics and materials that repel stains and have greater durability. There are several nanoparticles that can be added to clothing. One characteristic that these ultra-fine particles have in common is their small size, between one and 100 nanometers; or between one and 100 billionth of a meter. However, to take full advantage of this concept of fashion technology, it is essential to ensure that particles do not come off clothes during use or washing.

Basically, a material changes its behavior when its size decreases drastically. For example, not much can be done chemically with a piece of silver; however, when its size is reduced to a nanoscale, it can be added to fabrics to kill microbes.

This approach can prevent unpleasant odors from arising from sportswear by eliminating fungi and bacteria.

Different materials can also be combined to achieve the desired qualities. Other examples are antistatic and silica nanoparticles. Tin oxide mixed with antimony, titanium dioxide and zinc oxide are examples of antistatic nanoparticles. These particles conduct electricity that can disperse the static charge created when, for example, synthetic garments made of nylon or polyester are used. Silica nanoparticles can be incorporated into a fabric to create a water-repellent and stain-resistant garment.

Nanomaterials can be used to create clothing that is self-cleaning or even absorbs contaminants. This could result in cleaner air, as well as a reduced need for water and cleaning products. Imagine never having to do your laundry again!

Sustainable impact.

-

It reduces the need for water and cleaning products, as a garment is less prone to stains and odors or even cleans itself.

-

When each garment can be used many more times, the waste from the fashion industry can be reduced.

-

An extended clothing life cycle will decrease the need to buy new clothes because old clothes become torn.

Challenges to overcome.

-

There is still much to discover about the impact of nanoparticles on our planet and long-term living conditions. It is also essential to ensure that nanoparticles are not shed during the life cycle of a garment. For example, nanoparticles must not be absorbed by the skin or released in the washing machine and then enter fresh water.

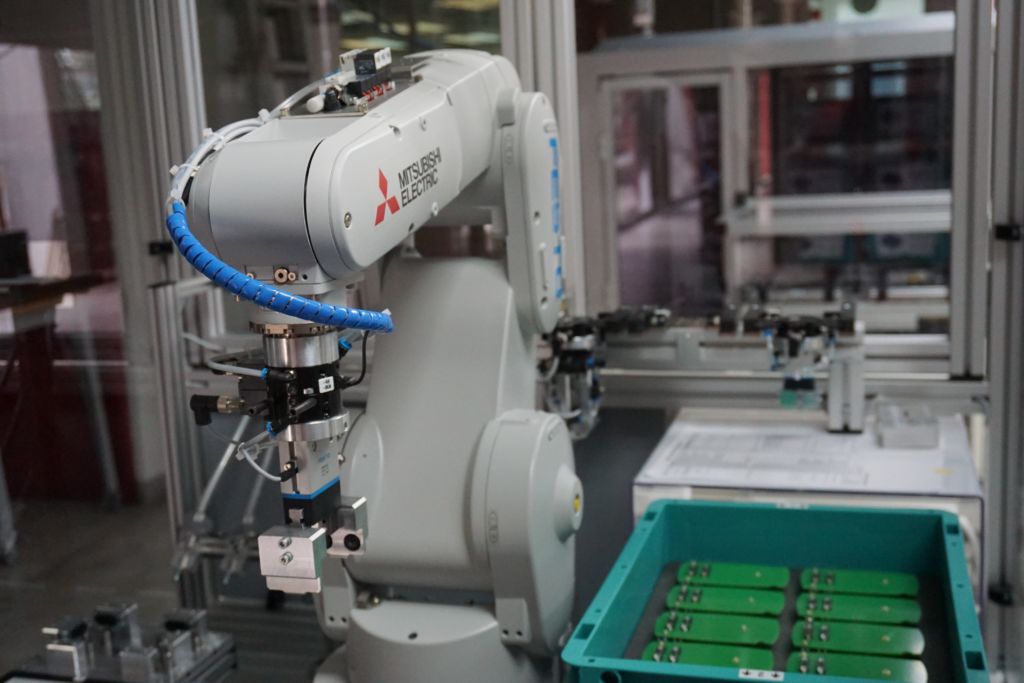

3. Robotics.

The concept of robotics in fashion technology has great potential for use throughout the fashion value chain.

Artificial intelligence (AI) consists of numerous technologies that can be combined so that intelligent machines can understand, act and learn.

AI is a successful driver of innovation and profit. If incorporated into the economy, AI can increase gross added value (a close approximation to GDP) by more than $2.2 trillion in the wholesale and retail sector by 2035, an increase of 59% compared to a stable situation. However, to unleash their full potential, organizations must first establish a mindset that puts people first.

For example, AI and analytics can allow for greater precision in forecasting and production planning. In this way, companies can reduce waste due to excessive stock levels and obsolete products. In addition, robotic process automation (RPA) can further help improve efficiency, accuracy, quality planning and monitoring by following defined principles.

For an automated physical production process, physical robots offer interesting opportunities. So far, the use of robots in the garment production process has been a challenge, due to the characteristics of soft materials and fabrics, as they are smooth, elastic and fragile. As we move forward, even the garment production process can be automated using technological advances such as IoT, IA and physical robots. More specifically, the movements of a robot could be carefully controlled using technology, continuously capturing and interpreting real-time photos of the garment. This helps to ensure that the fabric is handled correctly and not stretched too much.

In addition, physical robots can sort and collect waste. Automating this process improves productivity.

This concept of fashion technology shortens the distance between production and the user. In addition, the use of Artificial Intelligence allows workers to spend more time creating value rather than performing standardized routine tasks.

Sustainable impact.

-

It increases efficiency and accuracy in forecasting, minimizing waste and carbon footprint.

-

It reduces the need for transportation worldwide, as the production site and end user are closer to each other.

-

Positive social impact as technology supports labor and allows more time to be spent on value-added tasks.

-

Faster production processes reduce reliance on long-term forecasts, decreasing the risks of overstocking clothes and thus further minimizing waste.

Challenges to overcome.

-

Ensuring that organizations establish a mindset that puts people first and, through that, allows workers to be supported rather than replaced.

Let’s meet again in the next article to analyze the last of the circular fashion technologies, the biological technology. Thank you!