If client wants it, it will immediately be produced!

A “bomber” jacket, made of satin, with floral embroidery patterns in the front, back and sleeves, arrived at the store and was immediately put for sale at the flagship store of a famous international fashion brand in Mexico DF.

“For this season, clients are asking for floral-pattern embroidery with an Asian reminiscence”, explains the store manager while he shows the central embroidery in the back. “This information we submit from the stores, –he continues—is used to inspire designers who will create a new model that will arrive at the stores in few weeks. In the case of the ‘bomber’ jacket, the process took 30 days, which is the time that passed from the moment information was submitted from the stores to the central office until the arrival of the jacket at the shelves for display and sale”.

This story is in part an excerpt from an interview about fashion at the WSJ; I have changed the model and the subsequent process for the example mentioned because it is part of a past personal experience and I consider it more enriching for this article. It will be useful to analyze the successful business model born and strengthened in Spain: Fast fashion.

Immediacy, the key to success.

The journey from the drawing area in Europe to the store in Mexico DF is the central process by which fast fashion has transformed the essence of current textile industry and some of its brands into the largest global retailers.

This “Bomber jacket” is an example of the perfect process since the firm’s store assistants detect the clients’ desire for this type of model, communicate it to the “headquarters” and there, with great immediacy and versatility, the necessary decisions are made so that the garment is ready for sale within 4-5 weeks.

The process of fast fashion.

A pattern designer at the firm’s central hub in Europe has devoted four days to creating the prototype of the “bomber jacket” from information that arrived from stores in a specified region.

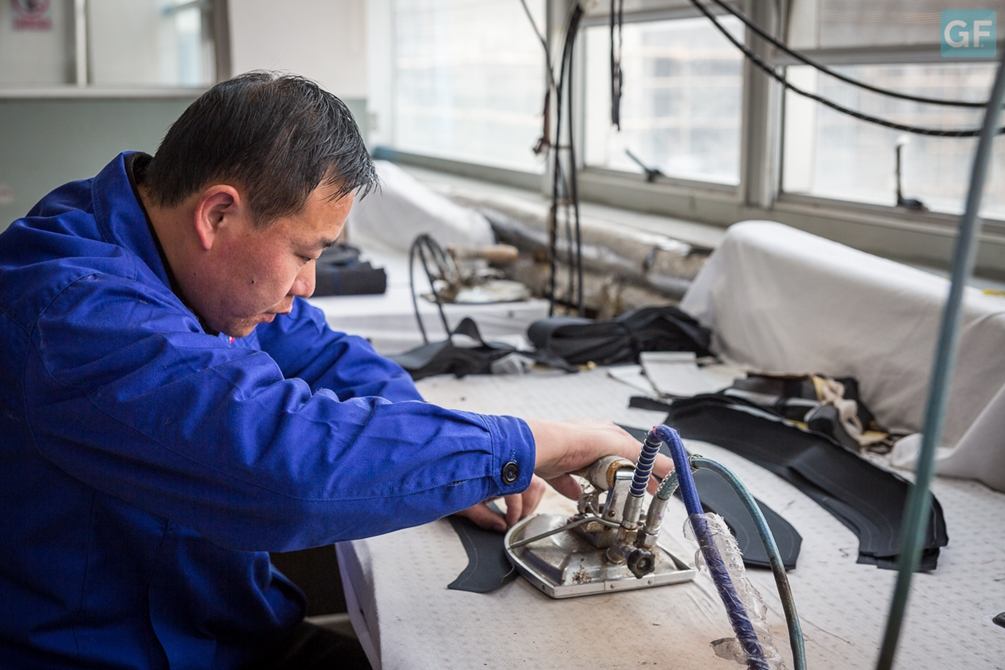

Once the production sample is approved, manufacturing of the model begins. In a fortnight, 10,000 units have been approved and manufactured in a near-shore factory in the Mediterranean Basin. In the next 6 days, garments are labelled and ironed; then they are dispatched to the centralized logistics hub in the same European city where the headquarters are located. Second quality inspections are run and garments are then distributed to stores in another continent.

The next day, the jackets are transported in trucks from the airport in Mexico DF to each store in the city and the rest of the country.

The ability of the brand that created this system to respond quickly to the customers’ demand is a matter of study and analysis for the rest of the competitors so that they can also develop the same process and obtain the superb results achieved by this firm.

Constant flow of information and immediate decisions.

The key points of this process are: the constant flow of business information from the global stores to the head office, and the fact that decisions to create, manufacture and distribute the product are centralized, agreed by the team, and immediate.

In my opinion, an aspect that is extremely important is that in addition to the professionals, each and every one of the departments in the organization collaborates towards this system. If a protocol or instruction delays or blocks it, it is immediately modified.

This is the true DNA whereby a company can become the fastest in the world when it comes to imagining, creating and putting for sale a new model in their international stores.

The formula of speed.

Part of the formula for producing something fast, cutting production times to the minimum possible, has been near-shore manufacturing. Europe does this in the Mediterranean Basin and Asia; America employs providers from Central and South America. But, since this is not enough, rationalization and optimization of design, manufacturing and logistics processes must be added. With this set of strategic and operational changes, there has been a significant reduction in delivery times from the inception of the garment until it reaches the stores.

The cause of success.

The cause of success of these few global labels is a sourcing strategy that is carefully planned but “short” for a set of models. Fast fashion is the ability to offer consumers designs that are not available yet from other retailers. In this sense, the concept of immediacy must be corporation-wide.

Any creative decision regarding the “bomber jacket” that we have discussed, as well as any other trending style, is automatically born from spontaneous contacts of professionals at headquarters. The physical layout of centralized offices and collaborators, sitting next to each other, fosters immediate, face-to-face contact when it comes to making decisions. In these areas, daily work is extremely versatile in order to respond quickly to current wishes of customers.

Thanks to this instantaneous system of inception and near-shore manufacturing, these brands can complete the process from an idea to the finished garment available at the store shelves within the same continent in just four weeks.

Efficient distribution to stores contributes to success.

These Fast Fashion brands have been developing a centralized logistics system whereby shipping from the factory to the store is a direct, lineal process, free of intermediate storage in most cases.

Centralization is again present, which in this case allows a more efficient control and, if it were planned, a faster, more thorough quality control of each unit in origin before they are shipped to the malls.

Bottom line.

Fast Fashion is an extremely successful model of creation, manufacturing and distribution nowadays. It will not be the last, but it still has a long way to go.

Scheduled production Vs. Instant production

Nevertheless, this process is only a part of a much more complex and rich strategic system that textile brands have today. There are even international fashion companies who have not invested in it and are still planning the sourcing of a large portion of their manufacturing –or almost all of it—six months in advance. Perhaps, the most important thing is to be congruent with the organization’s DNA and their long-term goals.

I extend my invitation to continue analyzing this fascinating model in the next articles.

Cheers!