As in other industries, the ability to bring in talent will be a key advantage in achieving success in the supply chain of the future. The greatest complexity in such recruitment today is in advanced digital production and in managing multi-modal sourcing decisions for the most complex garments.

Before we continue to analyze these profound changes in the industry and its structure, if you are interested in the organization chart and structure of fashion companies, here are the links to the previous articles where we examined it: Organization chart of a fashion company | Structure and organization of a fashion brand or company | Organization chart of a digital fashion company, its configuration and structure |

Fashion 5.0: modifying the organization’s DNA

Motivating employees to start and lead them on the journey from the “old” to the “new” supply system will be the backbone in this situation. The most successful players will undoubtedly start on the path, begin the process and develop their skills as they go along. Incorporating talent in this area will require fashion brands to create a very interesting value proposition for their collaborators.

Organizations cannot overlook the talent of the most experienced professionals who have deep knowledge not only in this particular sector but also in other industries. Collaborators with knowledge of the engineering that constitutes current, disruptive and future technologies are as transcendental as the technologies themselves.

It is highly possible that one of the most important tasks of companies is to be at the forefront of changes in the sector, developments in the industry and to decide clearly where to invest; for example, establishing partnerships, making acquisitions or having the internal talent to develop new technologies in-house. Basically, it is important to have professionals capable of identifying, researching and developing winning technologies.

Smart sourcing is multimodal sourcing.

The configuration of a multimodal sourcing system, whose main goal is a quick go-to-market, is more complex than a sourcing system solely focused on Asian origins, a model oriented towards achieving the best possible costs through large production volumes. In this reality, collaboration with suppliers is becoming more and more important and the aim is to build solid strategic partnerships. If companies already have the right professionals on their staff to manage this new reality, they have an advantage; if they do not, they should recruit them to increase the analytical and management skills of these relationships, which are crucial.

In addition to bringing in digital manufacturing knowledge and multi-modal sourcing skills, it will not be easy to recruit professionals who are sufficiently familiar with the reality of sourcing and who have the ability to expand supply by expanding capabilities and infrastructure in new, underdeveloped sourcing origins.

The goal is to spare no means and effort to find and generate these talents, while at the same time keeping them on the organization’s agenda. Cooperation with industry associations and local governments is essential to achieve the construction of new manufacturing conglomerates.

The new sourcing of fashion has already been born.

The generation of new skills and the change of mentality are fundamental to achieve success in this stage of transformation. The technological opportunities created by digitalization and automation, plus the need to accelerate analysis and review the entire apparel value chain, require a different, much more agile and customer-centric vision.

For many years, fashion brands and companies have acted under the precepts of the old sourcing system of the fashion industry, i.e. with an exclusive focus on the purchase price and, in some cases, it was taken to the extreme of a permanent search for the next opportunity to reduce FOB and for a low cost origin. Today, this sector’s players cannot generate value through that single strategy and therefore do not reach the proposed goals. Faced with this new reality, it has become vitally important to change the sourcing management and even the company’s DNA when it comes to constituting and strengthening an ecosystem of strategic partnerships.

Strategic partnerships with suppliers.

These types of partnerships are essential to obtain a lasting competitive advantage in the new market environment and in the context of confusion that reigns around winning technologies and the speed of innovation. Retail and fashion brands will have to create partnerships with different types of organizations and companies, even from other sectors.

They need to engage with major global suppliers to generate significant and optimal production capacity and to promote know-how and expertise from new sources. As robotization and automation will accelerate supplier consolidation, now is the best time to build such partnerships. This is a great opportunity for Asian industrialists to pioneer and drive forward the automation of the industry in local and near-shore origins.

In this scenario, brands must constitute these strategic partnerships based on the degree of automation of manufacturers and also on their skills and previous experience in the relocation of production in border markets, while, as always, ensuring “the ABCs of the sector”: sustainability, quality and productivity. A major change is needed in the relationship with suppliers to move from purely transactional and cost-oriented management to one that is much closer, proactive and has shared objectives.

Cross-sector partnerships.

If brands are to compete in an increasingly difficult market, they will need to collaborate more and more with technology companies and startups to develop innovative automation robotic solutions, as neither apparel brands nor most manufacturers are currently better positioned to develop the necessary disruptive technologies.

Companies must select their strategy to make this possible and cross-sector partnerships play a key role in this regard. Brands and retailers with sufficient financial means to invest in technology companies should consider doing so ASAP.

Investment to rebuild a vertical industry in proximity.

Private equity or venture capital firms can play a very active and leading role as financial partners in the partnership ecosystem; they can participate in investments in technology companies and also, more importantly, they can come to play a key role in capital investments to build local supply chains for nearshoring production.

As we have mentioned in previous posts, an important part of the production of fabrics has followed the manufacture of garments and for this reason, the latter is highly concentrated in China. The increase in textile production capacity in Eastern Europe and Central America will require large capital investments in textile factories. It is understandable that most apparel brands do not want to tie up capital in this part of the supply chain. Therefore, the creation of partnerships with private equity companies to leverage investment in fabric production in these proximity origins would be a means of enabling an end-to-end supply chain in the new locations.

This means the reconstruction of a vertical industry, which is a fundamental requirement for achieving maximum speed in the production process and in reaching the market. Being part of these partnerships, joining other stakeholders to drive investment and getting brands and retailers to commit to certain production volumes, should also play a key role in the partnership ecosystem.

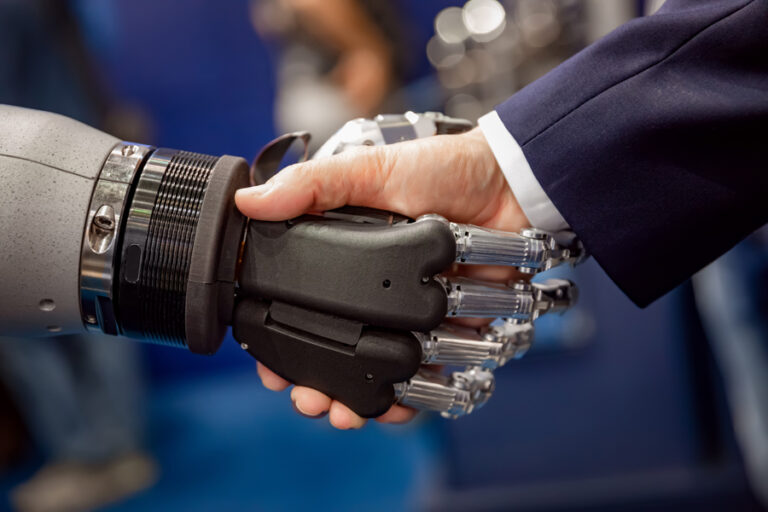

There is much potential to be recognized and much to be gained. With bold strategies, key industry players can position themselves competitively in the new scenario of fashion industry 5.0; an automated, high-value generating fashion industry, which is the result of a collaborative effort between people and robots.

Fashion 5.0 is neorelocalization.

The change from the traditional system has already begun and to the model of ultra fast fashion – producing at the highest possible speed, short series in small volumes, with the double objective of selling at full price and reducing stock – we must add sustainability. And being sustainable no longer only means producing the articles with certain organic, recycled or certified materials, but we must be much more transparent and generate traceability throughout the value chain. The means to achieve these goals is through technology and automation.

During this time and with a long road ahead, supply alternatives will be drastically reduced because only those textile manufacturers and industrialists who have begun their migration towards sustainability will be available options in the future; the rest will perish in their own inaction. Ultimately, achieving these goals will be possible thanks to the phenomenon we have been analyzing in this space: the neorelocalization of the fashion industry.