The Institut für Textiltechnik – ITA – is one of the leading research institutes in the field of materials, production processes and products for technical applications of textile structure. Together with the international consulting firm McKinsey and several technology providers, ITA recently opened the Digital Capability Center (DCC) – which acts as a platform for capacity increase in a real-world learning and demonstration environment, as well as a test base for testing and expanding new digital solutions.

Technological advances in the textile industry

Below, I share some of the concepts put forward by Dr. Yves Simon Gloy – director of ITA – in McKinsey’s Report on Provisioning and Digitization. He clearly tells us that the most profound change we will see in the fashion supply chain of the future is the ability to gather real-time data during the production process and use it to increase production efficiency. Production lines can be optimized by exchanging specific data and even individual processes (such as sewing) can be improved in terms of efficiency through automation, self-optimization and the use of artificial intelligence.

It’s the new industry 4.0! In this article we have analyzed it in detail, I recommend you to read it: Adapt or die: industry 4.0 puts textile in check.

Technological innovations in the textile and fashion industry

We are going to experience changes in how people interact with machines. In developed countries, human-machine interactions will be driven by demographic change and a shortage of skilled workers. Trends point to integrated production technologies and hybrid processes in which several steps are grouped into a single machine. Mass customization leads fashion and apparel brands to produce their models in the proximity of end consumers.

Innovations in the textile and fashion industry can be seen in the initial applications of human-machine communication, such as voice-controlled weaving devices. Other changes, such as artificial intelligence in big data, will take longer. Some technologies will take several years until they are mature enough, such as fully automated spinning. When comparing digital solutions, sensor-assisted production data collection – for example, with RFID – will have the greatest effect on process efficiency and product quality. The Adidas “factory-shop” is a good example of where things can go. It’s a new approach where product development, from custom design to production, actually happens in the store. Such an application is promising from an economic point of view.

Automation, robotics and RFID

Companies always need to consider the profitability of automation in mass production given the magnitude of the investments required. The use of robotics is already widespread in the production of automobiles and someday it could also be so in the sewing processes. The use of RFID – the technology for reading and transferring data – is also a very promising field, especially when applied to all stages, from manufacturing to the point of sale. Emerging textile technology and innovation companies are developing interesting solutions to optimize retail processes and create insights into customer behavior by “digitizing” garment production.

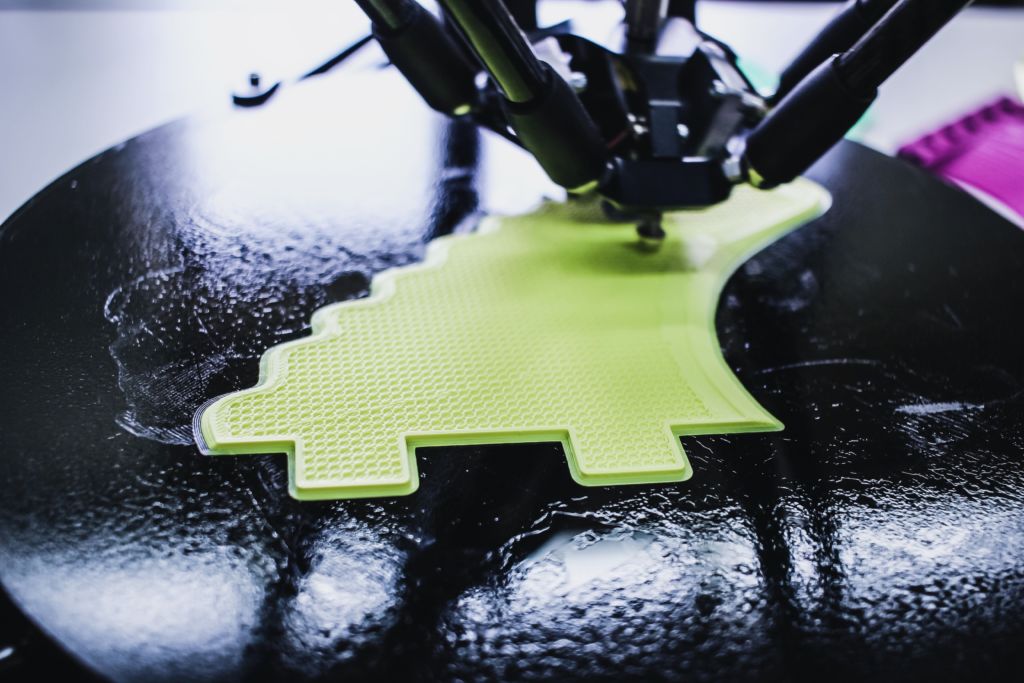

3D Design and printing.

In one of our articles we analyzed the benefits and progress of 3D design in the fashion industry and the great opportunities generated by its use in the process of creating and manufacturing models. However, Yves is a bit skeptical about 3D printing, believing that materials should be usable and comfortable. Therefore, he thinks that more innovations are needed in material development to get to the point where 3D printed products exhibit properties similar to textile fabrics. The maturity of digitization in the fashion industry is in the early stages. While some actors use RFID on the manufacturing floor and others use some human-machine interaction tools, self-optimization and robotics are not yet massively employed. There is a lot of interest, but implementation is still scarce.

Textile production technology.

The biggest obstacle to implementing digitalization is the human factor. The capacity of organizations and their employees to adopt, manage and implement new technologies in the textile and fashion industry is deficient. Therefore, fashion companies must seek partners and collaborate across industry boundaries. For this reason the creation of the CCD allows to test digitization solutions in addition to providing the means for implementation. It is also a learning facility, where you can see first-hand a digitized textile production line.

Ultimately, whether or not digitization causes a change in garment production (e.g., increasing nearshore production) depends on many more factors than just technological feasibility. But technological limitations must be overcome, especially in interface issues such as accessing data from older textile machines. In general, the greatest advantages of new technologies are that they make production more efficient and faster, offer higher quality, enable more personalized products and create new business models.

(7 votes, average: 4.14 out of 5)

(7 votes, average: 4.14 out of 5)